Introduction

In the global retail and exhibition world, choosing the right lighting manufacturer in China can shape the entire outcome of your brand experience. Good lighting doesn’t just “brighten a product”—it builds mood, creates perception, and determines how your customers feel when they stand in front of a display.

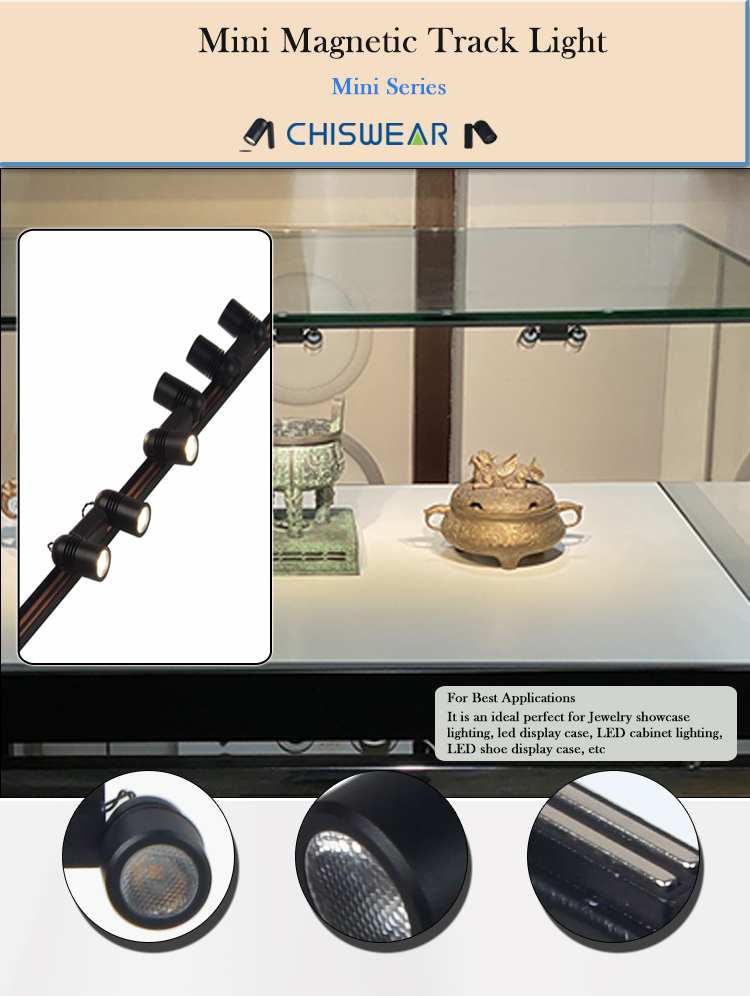

The challenge is not finding a supplier. The goal is to find one factory you can trust year after year. This matters for LED showcase lighting, jewelry display lighting, and mini magnetic track lights for display cases.

What Makes A Specialized Showcase Lighting Factory Different From A Regular LED Factory?

Are you wondering why you can’t simply buy from any LED factory in China? Many factories produce LED bulbs, downlights, or floodlights, but specialize in none. Showcase lighting, however, sits in a category of its own—one that demands precision that general factories can’t deliver.

A specialized showcase lighting manufacturer has deep expertise in:

- Controlled beam shaping

- CRI accuracy for product color

- Ultra-low heat output

- High-end industrial design

- Stable optical performance over long operating hours

These are not optional features; they are requirements if you want premium displays.

Why specialization matters

Think about jewelry shops. Luxury watches, high-end boutiques, makeup counters, or museums. Lighting here must be:

- Crisp

- Clean

- Balanced

- Precise

A wrong beam angle, a poorly mixed color temperature, or an overheated light source can ruin the entire display atmosphere.

General LED Factory vs. Showcase Lighting Specialist

|

Feature |

General LED Factory |

Showcase Lighting Specialist |

|

Beam Accuracy |

±20–30% variation |

±5% precision |

|

CRI Quality |

70–80 CRI |

90–98 CRI |

|

Heat Output |

Moderate to high |

Engineered low-heat optics |

|

Design Style |

Bulk, utility |

Slim, elegant, tailored |

|

Display Focus |

Not optimized |

Designed for jewelry/cosmetics/museums |

When browsing manufacturer catalogs, look for items like Mini LED pole lighting, magnetic track light systems, or LED jewelry lighting. These are strong signs of true specialization.

For inspiration, see the high-precision solutions on Chiswear Magnetic Track Lights

How Can You Check If A Manufacturer Keeps Strong And Steady Quality Control?

If you want long-term cooperation, quality stability matters even more than price. One batch that looks perfect and another that looks “slightly off” can damage your brand.

A professional manufacturer follows a strict quality pipeline that includes:

- Incoming IC, LED chip, and driver inspection

- Lumen and CRI testing

- Color temperature consistency checks

- Thermal management tests

- 24–72 hours aging tests

- Structured SOPs for every assembly step

Why QC matters in showcase lighting

Showcase lighting runs for long hours. A CRI drop, flicker, color shift, or early failure can:

- Distort product colors

- Reduce customer trust

- Increase return rates

- Cause reinstallation costs

Critical QC Factors You Must Confirm

|

QC Check |

Why It Matters |

What You Should Ask the Factory |

|

CCT Testing |

prevents visible color mismatch |

“Do you test every batch or only sampling?” |

|

CRI Inspection |

ensures accurate product appearance |

“Can you provide CRI test records?” |

|

Thermal Analysis |

protects LEDs from early aging |

“What temperatures do you test under?” |

|

Aging Test |

catches weak soldering or unstable drivers |

“How long do you age each batch?” |

|

Incoming QC |

ensures high-grade components |

“Do you reject LED chips that deviate?” |

A manufacturer who is truly confident will show you test reports before you ask.

How Do You Know If A Chinese Factory Can Follow Design Changes And New Market Trends?

Showcase lighting moves fast. Trends shift. Product standards evolve. Customers request new mounting styles, tighter beam angles, or leaner designs. The best factories have R&D teams who can create solutions quickly—not just assemble whatever is handed to them.

What strong R&D support looks like

A capable partner should offer:

- Custom beam angle designs

- Special CCT tuning (e.g., 3700K for gold jewelry)

- Custom lens or reflector modules

- Bespoke PCB layouts

- Ultra-thin housings for modern showcases

- Color-matched finishing (champagne gold, matte black, brushed silver)

- Dimmable drivers (0–10V, TRIAC, DALI)

This matters most in luxury, boutique, and bespoke retail. Here, looks shape how people see you.

Example: Magnetic showcase systems

Many modern brands now prefer minimalist track systems like:

- Magnetic showcase track lighting

- Mini magnetic showcase track lighting

These systems allow easy installation, precise beam shaping, and beautiful display integration. A general LED factory may not even know how to produce these.

To view real examples, check Chiswear LED Jewelry Display Lights

R&D Capabilities Checklist

|

Feature |

Why You Need It |

What to Look For |

|

Lens Engineering |

display beam precision |

in-house optical designers |

|

PCB Customization |

smaller or cooler fixtures |

SMT equipment, design team |

|

Housing Colors |

luxury branding needs |

anodizing or powder-coating options |

|

Dimming Protocols |

compatibility with global markets |

TRIAC, DALI, PWM, 0–10V |

Why Does A Stable Supply Chain Matter So Much With Chinese Lighting Partners?

Even the best product design is worthless if the materials are unstable. Showcase lighting—especially premium formats like magnetic track light or LED jewelry lighting—requires stable components that won’t disappear suddenly from the market.

Common component risks in China

- LED chips discontinued without notice

- Driver IC shortages

- Inconsistent aluminum quality

- Lens suppliers changing formulas

- Variations in connector materials

A reliable manufacturer should guarantee:

- Mainstream LED chip brands (Osram, Cree, Bridgelux, Nichia)

- Driver suppliers with 3–5 year stability records

- Fixed supply agreements with optical material vendors

- Backup suppliers for key components

Component Stability Matrix

|

Component |

Risk Level |

What You Should Confirm |

|

LED Chips |

High |

brand, batch IDs, continuity plan |

|

Drivers |

High |

certifications, supplier agreements |

|

Optics |

Medium |

material source and mold control |

|

Aluminum |

Low |

extrusion consistency |

|

Connectors |

Medium |

exact production source |

Supply chain is the hidden backbone of long-term reliability.

Can The Factory Manage Both Small Custom Orders And Big Long-Term Rollouts?

Showcase lighting businesses rarely place the same quantity every month. Designers may order 10 units today, a mall project may require 2,000 next month.

A good manufacturer must handle both.

Small batch capabilities you should confirm

- Ability to produce 10–50 custom units

- Quick sampling (5–7 days)

- Willingness to produce custom optics or housing colors

- Ability to match color temperature for tiny orders

- Multiple SMT production lines

- Automated aging racks

- Skilled workforce for delicate assembly

- Predictable lead times

- Inventory planning for recurring orders

Large batch capabilities you must verify

Small vs. Large Order Requirements

|

Requirement |

Small Orders |

Large Orders |

|

Speed |

5–7 days |

15–30 days |

|

QC |

batch-level |

batch + line QC |

|

Flexibility |

very high |

structured but consistent |

|

Cost |

slightly higher |

optimized pricing |

If your supplier can only handle one side, they will bottleneck your growth.

Conclusion

Choosing a Chinese manufacturer for high-end showcase lighting is not just about comparing prices. It means choosing a partner who gets your vision and keeps lighting sharp. You both grow side by side.

A strong manufacturer sees your project as a long-term partner. They back your ideas with innovation, quality, and clear communication. When you choose well, every light in your display works for you. Each beam, from magnetic track to LED showcase lighting, becomes an investment.

External Links:

- https://en.wikipedia.org/wiki/Color_rendering_index

- https://en.wikipedia.org/wiki/Color_temperature

- https://www.indeed.com/career-advice/career-development/example-of-sop

- https://www.electronics-tutorials.ws/power/triac.html

- https://www.dali-alliance.org/certification/

Post time: Dec-02-2025