Introduction

In showcase and display lighting, safety is not extra. It is part of the design. When you light a jewelry cabinet, museum case, or luxury retail wall, the system must pass strict electrical and safety checks before anyone can sell or install it.

One simple way to make life easier is to move away from mains power (110–240 V AC) and use low-voltage 12 V or 24 V DC systems instead. In this guide, we’ll look at why low-voltage LED showcase lighting helps with certification, reduces risk, and gives you more design freedom. We’ll also connect these ideas to products like magnetic track light systems and mini spotlights used in real projects.

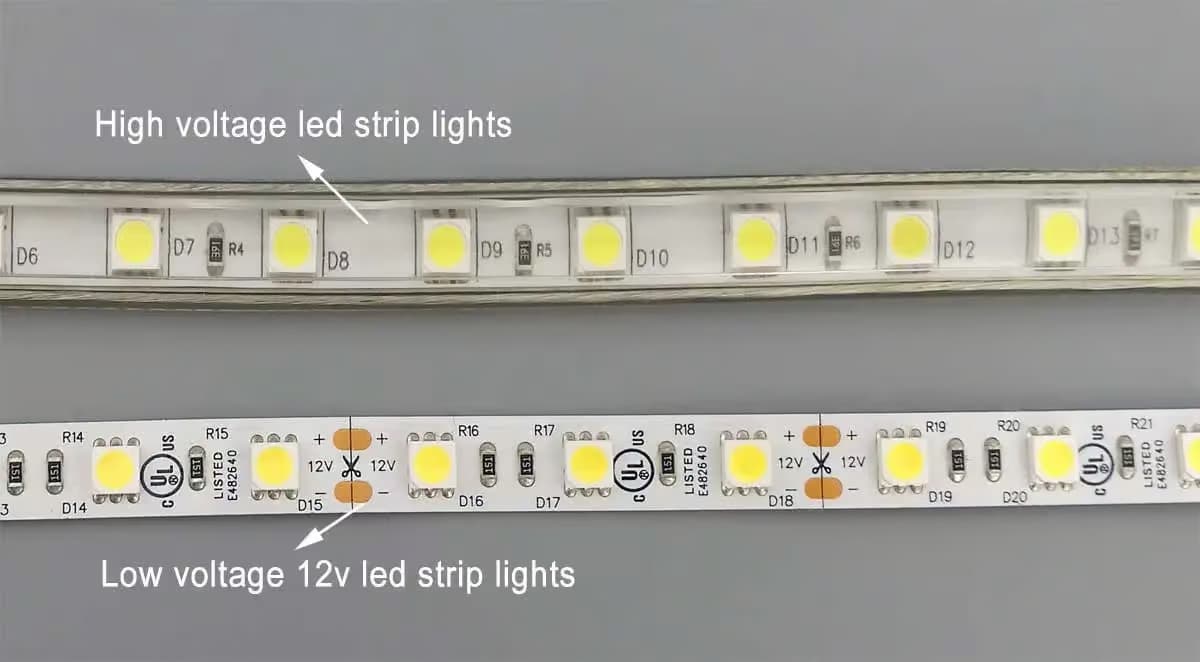

What Does “Low Voltage” Mean In Showcase Lighting?

In lighting, low voltage usually means 12V. It can also mean 24V DC. Power from the wall at 110–240 V AC enters a power supply or LED driver. There it gets stepped down and converted. Then the safe, low-voltage side feeds the light modules inside the cabinet.

In many standards, this sits in the Safety Extra Low Voltage (SELV) range. SELV systems are designed so that, even if a fault happens, the voltage at any point people can touch stays low enough to reduce shock risk.

Here’s a simple comparison:

|

Item |

Mains System (110–240 V AC) |

Low-Voltage System (12 / 24 V DC) |

|

Typical voltage level |

110–240 V |

12–24 V |

|

Shock risk |

High |

Much lower (SELV range) |

|

Where the risk is |

In the whole circuit |

Mostly inside the driver |

|

Common use |

Room lighting, building |

Jewelry showcase lighting, mini tracks, LED bars |

How Does Low Voltage Reduce Risk And Make Safety Tests Easier?

Why do test labs like low-voltage systems? Because they are safer by design.

With a SELV-level system, the chance of a dangerous shock drops a lot. Standards for SELV circuits focus on keeping the voltage low, spacing and insulation correct, and making sure faults don’t push the system above safe limits.

Which Certification Steps Become Simpler With Low-Voltage Systems?

When you design a 12 V or 24 V showcase system, several certification steps often become lighter or faster:

- Insulation and spacing checks

○ High-voltage lights need safe gaps. Live parts must stay away from metal you can touch.

○ On the low-voltage side, the needed gaps are smaller. This makes PCB layouts and connector designs easier to approve.

- Dielectric strength tests

○ Mains-driven luminaires may need high-voltage dielectric tests between input and accessible parts.

○ Low-voltage modules usually face lower test voltages on the output side, which is less stressful and quicker to run.

- Use of pre-certified LED drivers

○ LED drivers with UL, ENEC, or similar marks meet safety and efficiency rules. These include UL 8750 and EN 61347-1.

○ When your cabinet lights run on 12V or 24V DC, use a certified driver. Then connect your low-voltage modules safely and securely. This means the fixture has to go through fewer tests overall.

- EMC (Electromagnetic Compatibility)

○ EMC rules control how much electrical noise your system makes. They also say how stable it must stay around interference.

|

Certification Step |

Mains-Integrated Design |

Low-Voltage + External Driver |

|

Driver safety approval |

Done per fixture |

Done once, reused across projects |

|

EMC testing |

Per fixture, full system |

Focused on driver; modules simpler |

|

Documentation load |

More component-level evidence |

Driver reports reused, fewer new reports |

|

Time to market |

Longer test loops |

Shorter, especially for repeat projects |

Why Is Low Voltage Better For Retail, Museum, And Jewelry Displays?

Showcases are close to people, products, and sometimes priceless artifacts. Low voltage helps in three key ways: heat, touch safety, and service.

- Lower heat near products

- Safer human interaction

- Easier maintenance

How Does Low Voltage Improve Design Flexibility And Product Choice?

Low-voltage systems unlock slimmer, smarter fixtures. You are no longer trying to hide bulky mains parts inside a 6–10 mm profile.

This is where products like mini showcase track lighting and mini LED pole lighting shine. Powered by 12 V or 24 V rails, they can be tiny, movable, and precise, yet still strong enough for diamond or watch displays.

On chiswear.com, you’ll find compact magnetic track light modules designed for museum and jewelry displays. One 3 W 12 V module, for example, offers a rotatable head and tight beam control, ideal for highlighting small items in a cabinet.

Here’s how low voltage supports design:

|

Product Type |

Typical Voltage |

What Low Voltage Enables |

|

Magnetic track lighting |

12–24 V DC |

Safe, click-in modules that can move anytime |

|

Mini LED bars |

12–24 V DC |

Ultra-slim profiles under shelves and frames |

|

Mini LED pole lighting |

12–24 V DC |

Tiny poles that lift light right above products |

|

Spot modules for LED showcase lighting |

12–24 V DC |

High CRI beams with less glare and reflection |

How Does Low Voltage Help With Certification In Different Regions?

You may plan one showcase system and roll it out across several countries. Low voltage makes this easier because many rules center on the same core idea: keep the user away from dangerous energy.

North America (UL / ETL)

In the U.S. and Canada, LED drivers and luminaires often follow UL 8750 for LED equipment and related safety standards.

- If the driver is certified and outputs SELV 12–24 V DC, the showcase modules can be tested as part of a low-voltage system.

- Getting an ETL or UL listing for such a system usually involves less complex high-voltage work on the cabinet side; much of the burden sits inside the driver.

European Union (CE / ENEC)

In Europe, you must meet:

LED drivers are tested to two main standards. EN 61347-1 checks safety, and EN 62384 checks performance. Products with the ENEC mark clearly meet all these safety standards.

When your cabinet uses low-voltage LED modules fed by an ENEC-marked driver, your CE technical file is easier to build. You reuse the driver’s test reports and focus your own risk analysis on:

- Wiring and connectors

- Mechanical safety

- Temperature rise inside cabinets

Asia & Middle East

Many markets in Asia and the Middle East accept CB Scheme reports and then apply local marks such as SASO. Starting from a low-voltage base again helps:

- The same CB reports for drivers and LED modules can be reused.

- National labs focus on local labeling and basic safety checks, not full re-testing at every level.

What Should Buyers And Designers Check Before Approving A Low-Voltage System?

Even with low voltage, not all systems are equal. When you plan a new showcase line or store fit-out, use this checklist:

- Confirm true 12 V or 24 V design

○ Make sure the cabinet-side wiring and modules are all on the low-voltage side.

○ Ask where the driver sits and how mains enters the system.

- Ask for driver certificates and reports

○ Request UL / ENEC / CB documents for the LED drivers.

○ This proves the power stage already meets global rules.

- Review wiring, connectors, and installation method

○ Are cables clearly marked and easy to route?

○ Do tracks or poles click in safely, like magnetic showcase track lighting systems that prevent loose contacts?

- Partner With Manufacturers Who Understand Global Compliance

○ Pick suppliers who understand compliance, like Chiswear. This makes UL, CE, ENEC, and CB approvals much faster, safer.

Conclusion

Low-voltage 12 V and 24 V systems do more. They power more too. They make certification easier and lower risk for both staff and customers. You also get slimmer, more flexible designs for LED and jewelry showcase lighting.

When you combine low-voltage power with well-designed mini bars, magnetic tracks, and pole lights, you get showcases that are safe, compliant, and beautiful—without extra hassle in every new store or country.

External Links:

- https://en.wikipedia.org/wiki/Low_voltage

- https://maclean.pro/blogs/kennisbank/safety-extra-low-voltage-selv?srsltid=AfmBOopngGO85l_wbeqeSNfBDFKnUA0G5Bv7Qq4yfdxa5uzG27asybv7

- http://effectslayouts.blogspot.com/

- https://en.wikipedia.org/wiki/Low_Voltage_Directive

- https://environment.ec.europa.eu/topics/waste-and-recycling/rohs-directive_en

- https://www.saso.gov.sa/en/pages/default.aspx

Post time: Jan-16-2026