Introduction

Big lighting projects seem easy. You pick track lights, choose beam angles, install them, and move on, but real projects are almost never that simple. Small mistakes in your lighting plan add up. They cause uneven light, dull products, and high repair costs in many stores and showcases.

Showcase systems such as magnetic track lighting, mini track heads, and slim bars give you far more control. But they only work in your favor if the specification is clear from day one.

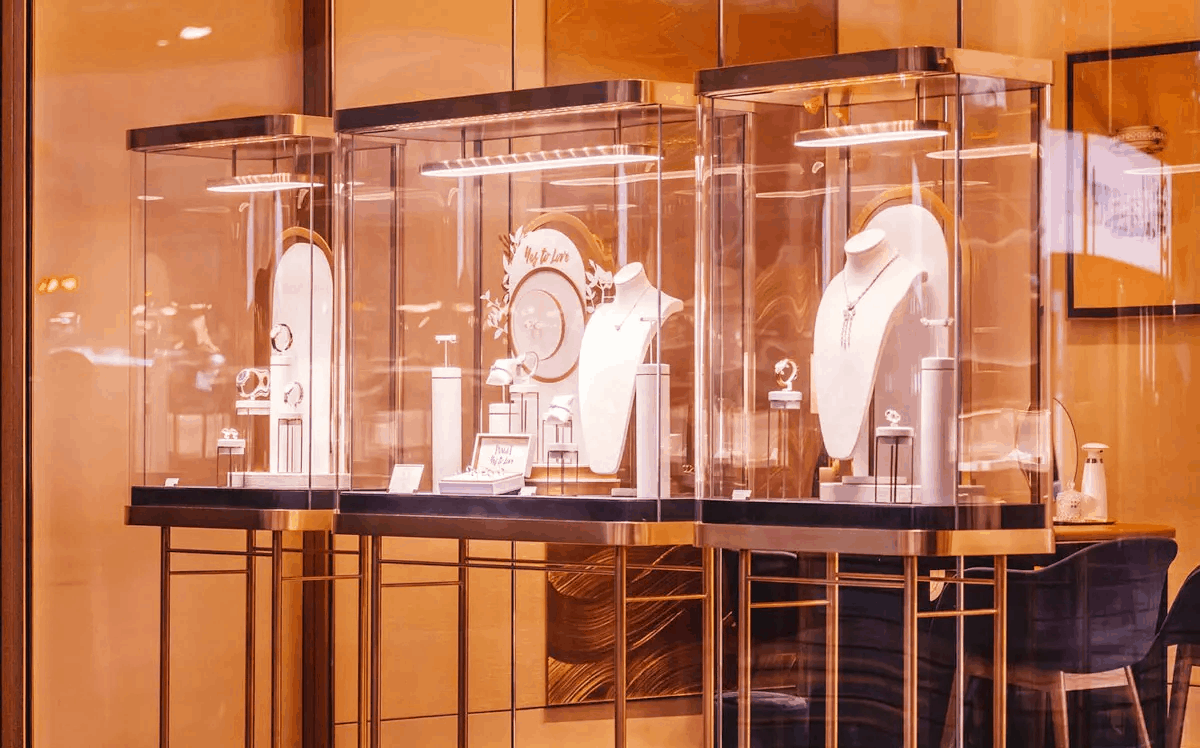

This guide walks through the most common spec errors buyers make and shows how to avoid them using smart LED showcase lighting choices, including solutions like magnetic showcase track lighting and mini showcase track lighting used in retail, museum, and luxury jewelry projects.

What Makes Track Lighting For Large Projects So Easy To Get Wrong?

When you order lights for a single boutique, you can “fix things on site.” On a chain roll-out or museum upgrade, every mistake multiplies. One wrong track type, one poor beam choice, or one weak driver spec can affect tens or hundreds of showcases.

Typical pain points in big projects:The good news: most of this is avoidable if you slow down at the spec stage and ask the right questions.

Why Is Choosing Track Lights On Price Alone A Problem?

Are you tempted to pick “the cheapest track light that meets the wattage”? That is one of the fastest ways to hurt a large project.

Low-cost fixtures often cut corners on:

- LED chip quality

- Driver stability

- Color rendering and consistency

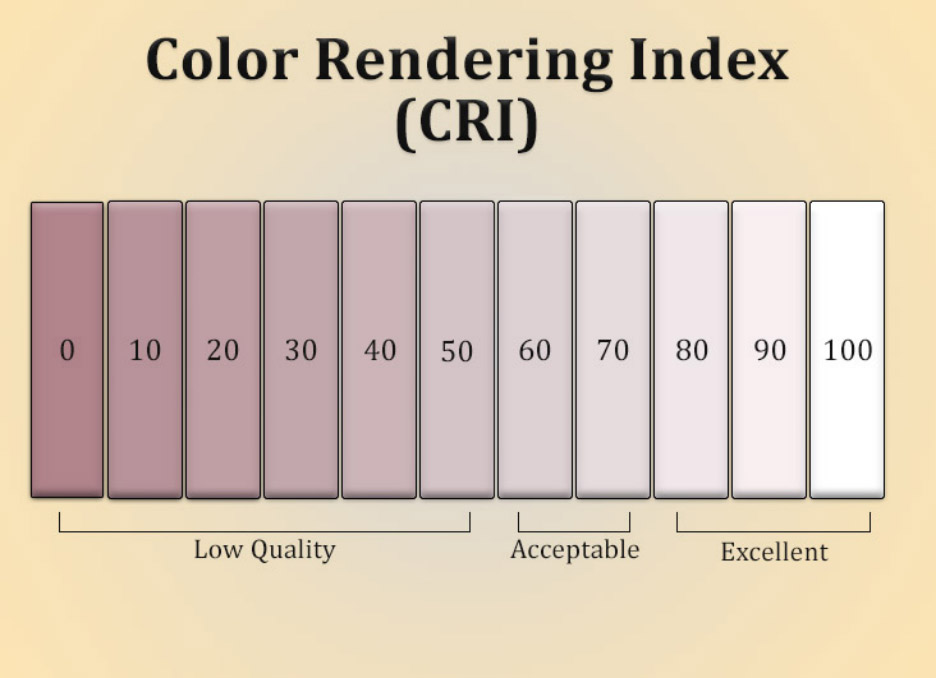

High CRI (Color Rendering Index) LEDs make colors look more natural and vibrant. Cheap LEDs often have low or unstable CRI, which makes merchandise look lifeless.

If you are lighting high-value items, a quality magnetic track light or mini LED spot will usually pay for itself in better sales and fewer failures. You can see examples of this approach in Chiswear’s magnetic track light collection.

How Does Light Quality (CRI And CCT) Affect Your Displays?

Have you ever seen a diamond that looked “yellow” under the wrong light? That is often a CRI and CCT problem, not a stone problem.

- CRI (Color Rendering Index) tells you how accurately colors appear under a light compared to natural daylight. Higher is better, especially for retail and museum work.

- CCT (Correlated Color Temperature) describes whether the light feels warm, neutral, or cool (in Kelvin).

Quick CRI & CCT Guide For Showcase Projects

|

Application |

Recommended CRI |

Common CCT Range |

Why It Works |

|

Jewelry showcases |

90+ |

3000K–4000K |

Natural sparkle, rich metals and stones |

|

Luxury fashion & leather goods |

90+ |

3000K–3500K |

Warm, premium feel, true color of fabrics |

|

Museums / artifacts |

90+ |

3000K–4000K |

Neutral tone, clear detail without harshness |

|

Tech / eyewear / modern retail |

90+ |

4000K–5000K |

Crisp, “tech” look, bright whites |

To go deeper into CRI basics, you can check guides like Liquid LEDs’ plain-language CRI explanation or Philips’ overview on color quality for LEDs.

On the product side, Chiswear’s jewelry showcase lighting range is built around high-CRI LEDs tuned for display cabinets, so metals, gems, and fabrics don’t lose their natural color.

How Should You Plan Beam Angles And Light Distribution?

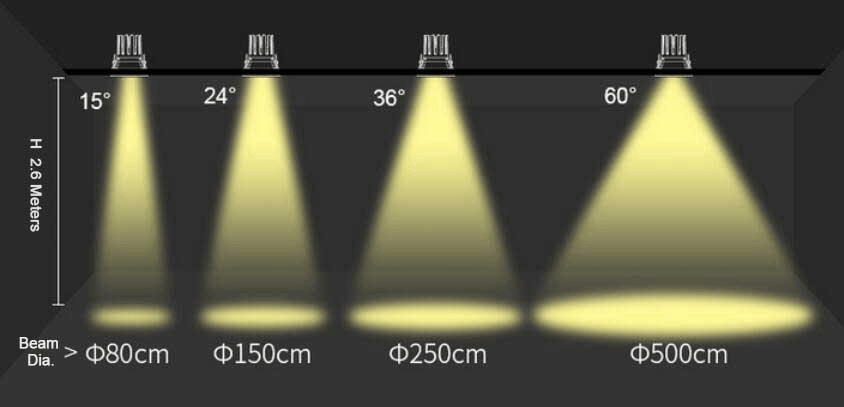

Many buyers pick “one beam angle that works everywhere” and hope for the best. That is a common reason large projects end up with bright hot spots and dark corners.

In track systems, you have three main tools:

- Narrow beams for highlight and sparkle

- Medium beams for general product wash

- Wide beams for ambient fill and wall washing

Why Does Flexibility And Modular Design Matter In Large Rollouts?

Do your displays stay the same for five years? Probably not. New collections, new promotions, and seasonal layouts all need new light positions.

If your system is rigid:

- Every layout change needs new wiring or new fixtures

- Your team spends time and money “fighting” the ceiling or showcase

Modular systems solve this. With magnetic track lighting, the track stays in place while you slide or click heads where you need them. You can also pair mini showcase track lighting and mini LED pole lighting for details at shelf level.

What Happens When You Ignore Power, Drivers, And Controls?

In big projects, it’s easy to think “a track is a track” and forget the electrical side. That is where flicker, random dimming issues, and driver burn-out start.

Common mistakes:

- Mixing fixtures that need different drivers on the same run

- Forgetting dimming protocol (0–10V, DALI, or simple on/off)

- Overloading a low-voltage driver with too many heads

Many magnetic showcase track lighting products, like the 12V mini systems on Chiswear, are built as complete low-voltage solutions, so the driver and track are already matched.

Why Is Thermal Management So Important In Enclosed Showcases?

LEDs run cooler than old halogens, but they still generate heat. In a closed glass case, a dense line of track heads can push temperatures up fast.

If you skip thermal planning:

- LEDs run hotter than they should

- Lumen output drops, and colors shift over time

- Product materials (leather, paper, cosmetics, even food samples) may suffer

How Good Thermal Design Protects Your Investment

|

Element |

Poor Design |

Good Design |

|

Heat path |

Plastic body, no heat path |

Aluminum body and heat sink fins |

|

Case ventilation |

Fully sealed, no airflow |

Hidden vents or gaps for slow air exchange |

|

LED lifetime |

Drops sharply at high temp |

Stays within spec for many years |

|

Product safety |

Risk of softening, fading, or warping |

Temperatures kept within safe range |

If you work with jewelry display showcase lighting, this is especially important, because some materials (like glues, packaging foams, or watch straps) are sensitive to heat over time.

How Do Serviceability And Maintenance Shape Lifetime Cost?

A light that is hard to service is an expensive light, no matter how cheap it was on day one.

Questions many buyers forget to ask:

- Can you replace just the LED module or driver, or do you replace the whole head?

- Can staff access the track without taking apart the whole cabinet?

- Are part numbers clear and documented across all locations?

Service-Friendly Vs Service-Heavy Systems

|

Aspect |

Service-Unfriendly System |

Service-Friendly System |

|

Module replacement |

Whole head or case must be removed |

Swappable heads, simple connectors |

|

Access in cabinet |

Needs disassembly or glass removal |

Top or front access with simple tools |

|

Documentation |

One-off specs, inconsistent part codes |

Standard SKUs and clear drawings |

|

Downtime per failure |

Hours, often after-hours work |

Short, often handled by in-house staff |

Showcase ranges like magnetic track lighting and mini track heads on Chiswear are designed so fixtures can be swapped without touching the wiring inside the case. That design choice alone can cut maintenance labor costs across a large chain.

Are All Track Systems And Fixtures Really Compatible?

One of the biggest surprises in projects is track compatibility. Not every head fits every rail. Even within “3-circuit” or “single-circuit” families, there are different physical standards.

With magnetic track lighting, you also need to match:

- Track shape (recessed, surface, pole, or slot)

- Track profile (round track pole vs flat track pole)

- Voltage and connector design

Before you confirm a spec, map your whole system: tracks, connectors, corners, power feeds, and each type of head.

How Can Better Communication And Visual Targets Save Your Project?

Another common mistake: buyers do not explain the visual goal. They simply send a floor plan and a wattage range.

Suppliers then guess:

- How bright should the hero tables be vs background walls?

- Which zones need punchy highlights vs soft halo light?

- How much contrast is right for this brand?

Instead, share:

- Sketches or photos of the mood you want

- Key “hero” products and zones

- Any corporate brand guidelines for light levels or temperatures

If you already know you want LED jewelry lighting or jewelry display showcase lighting, say this up front. It helps your supplier choose optics, color temperature, and mounting that fit these needs instead of guessing.

Conclusion

Large track lighting projects do not fail because of one big decision. They fail because of many small ones. By slowing down at the spec stage and asking simple, clear questions, you can turn track lighting into a stable, flexible asset instead of a yearly headache. When you combine these with a clear visual brief, your showcases stay bright, consistent, and on-brand—from the first installation to many seasons down the line.

External Links:

- https://en.wikipedia.org/wiki/High-CRI_LED_lighting

- https://liquid-leds.com/en-au/pages/understanding-cri-in-led-lighting

- https://en.wikipedia.org/wiki/Correlated_color_temperature

Post time: Jan-13-2026